Processing Materials: iron ore, copper ore, gold ore, limestone, calcite, barite, dolomite, potassium feldspar, marble, talcum, gypsum.

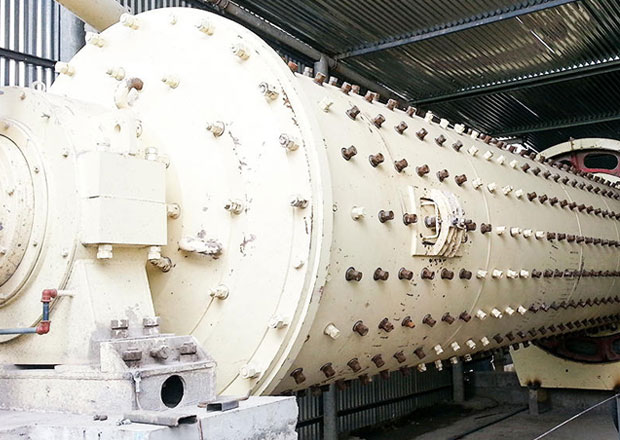

CONTACT USIt is mainly used for materials mixing and grinding, which can be used in dry grinding, but also in wet grinding. It can provide unparalleled crushing performance in a wide range of medium, fine, ultra-fine crushing operations from stone production to various ore crushing. Ceramic ball mill is the latest generation of products that can replace spring cone crusher and the upgrade general hydraulic cone crusher in the mining construction industry. It is also the ideal equipment for large-scale stone factories and mining crushing.

1. More uniform product particles the product particles after grinding are more uniform. Comparing with traditional equipment, it has about 25% higher output, approximately 26% lower unit electricity consumption and few grinding media consumption.

2. Cost savings first of all, the large and small gear of Ceramic ball mill transmission is very smooth. The gears can be turned over when they are worn to a certain extent and continue to use, which shorten parts replacement cycle and save a certain cost for customers.

Ceramic ball mill is a new type of energy-saving ball mill that liner is made of ceramic, it is researched and developed through combining with the latest ball milling technology by our company ore beneficiation machinery experts. The grinding fineness can be controlled according to grinding time. This equipment is energy-saving, easy to operate and stable in performance. Strong adaptability to materials, continuous production, large production capacity and crushing ratio can meet the requirements of large-scale industrial production, and easy to adjust grinding products fineness.

A super-large-scaled modern green industrial workshop 260000 square meters, large and medium-sized gold processing, maohan, assembly equipment more than 600 sets.

CONTACT US

| Model | Feeding capacity (t/time) |

Shell rotation speed (r/min) |

Reference motor (kw) |

Liner material |

| 600×700 | 0.05 | 50 | 2.2 | Chinaware,silicon,rubber or metal(the related motor power varied as per the different liner materials and grinding materials) |

| 800×600 | 0.075 | 42 | 3 | |

| 900×1200 | 0.2 | 38.5 | 5.5 | |

| 1300×1500 | 0.5 | 33 | 7.5 | |

| 1500×1800 | 1.2 | 28.5 | 11 | |

| 1800×2000 | 1.5 | 24 | 15 | |

| 2600×2800 | 5 | 16.5 | 37 | |

| 3000×3800 | 10 | 14.5 | 57.2 | |

| 3200×4600 | 15 | 13.5 | 75 |

| Model | Feeding capacity (t/time) |

Shell rotation speed (r/min) |

Liner material |

| 600×700 | 0.05 | 50 | Chinaware,silicon,rubber or metal(the related motor power varied as per the different liner materials and grinding materials) |

| 800×600 | 0.075 | 42 | |

| 900×1200 | 0.2 | 38.5 | |

| 1300×1500 | 0.5 | 33 | |

| 1500×1800 | 1.2 | 28.5 | |

| 1800×2000 | 1.5 | 24 | |

| 2600×2800 | 5 | 16.5 | |

| 3000×3800 | 10 | 14.5 | |

| 3200×4600 | 15 | 13.5 |