Application Areas: metallurgy, building materials, refractory materials, river pebbles.

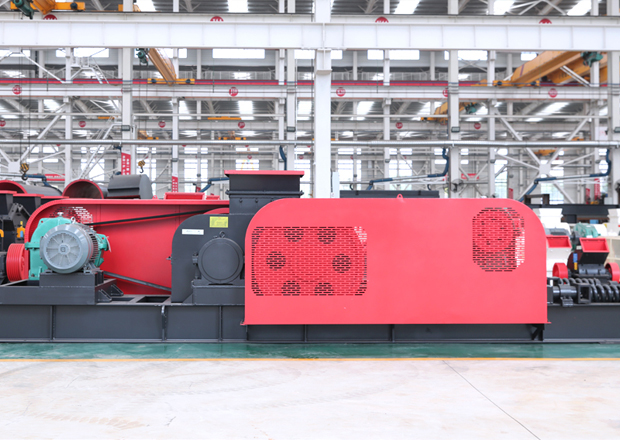

CONTACT USThis roll crusher is a crushing equipment developed by our company for coarse and fine crushing. The roller crusher is widely used in metallurgy, building materials, refractory materials and other industrial sectors to crush medium and high hardness materials. It has the characteristics of low noise, less dust, reliable performance and convenient maintenance.

This kind of crusher is a crushing equipment developed by our company for coarse and fine crushing. The roller crusher is widely used in metallurgy, building materials, refractory materials and other industrial sectors to crush medium and high hardness materials.

1. Unique structure

2. Operation cost is low

1) Low noise and reliable performance

2) High production efficiency and large processing capacity

3) Consumable parts have long life and low loss

3. Easy operation

Its gear transmission consists of a fixed roller, a movable roller, a transmission shaft, a body, a chassis, a cover, a long gear cover, etc. The machine power is transmitted from a triangular pulley on the motor, and then through a pair of intermediate reduction gears. The gear rotates the fixed roll and by means of a pair of long gears at the other end of the fixed roll, the movable rolls are driven, and the two rolls are pressed to press the material in relative motion.

A super-large-scaled modern green industrial workshop 260000 square meters, large and medium-sized gold processing, maohan, assembly equipment more than 600 sets.

CONTACT US

| Model | Roller diameter (mm) |

Roller Width (mm) |

Input Size (mm) |

Dischargine Gate (mm) |

Capacity (t/h) |

Power Models | Motor Power (KW) |

| 2PG0425 | Φ400 | 250 | ≤25 | 2-8 | 5-10 | Y132M-6 | 5.5×2 |

| 2PG0640 | Φ600 | 400 | ≤25 | 2-8 | 10-20 | Y160L-4 | 15×2 |

| 2PG0740 | Φ700 | 400 | ≤25 | 2-8 | 15-30 | Y200L-4 | 30×2 |

| 2PG0850 | Φ800 | 500 | ≤25 | 2-8 | 20-40 | Y225M-4 | 45×2 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Input Size (mm) |

Dischargine Gate (mm) |

Capacity (t/h) |

| 2PG0425 | ≤25 | 2-8 | 5-10 |

| 2PG0640 | ≤25 | 2-8 | 10-20 |

| 2PG0740 | ≤25 | 2-8 | 15-30 |

| 2PG0850 | ≤25 | 2-8 | 20-40 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.