According to the processing materials: it can be divided into cement kiln (see the details below), metallurgy chemical kiln and lime kiln.

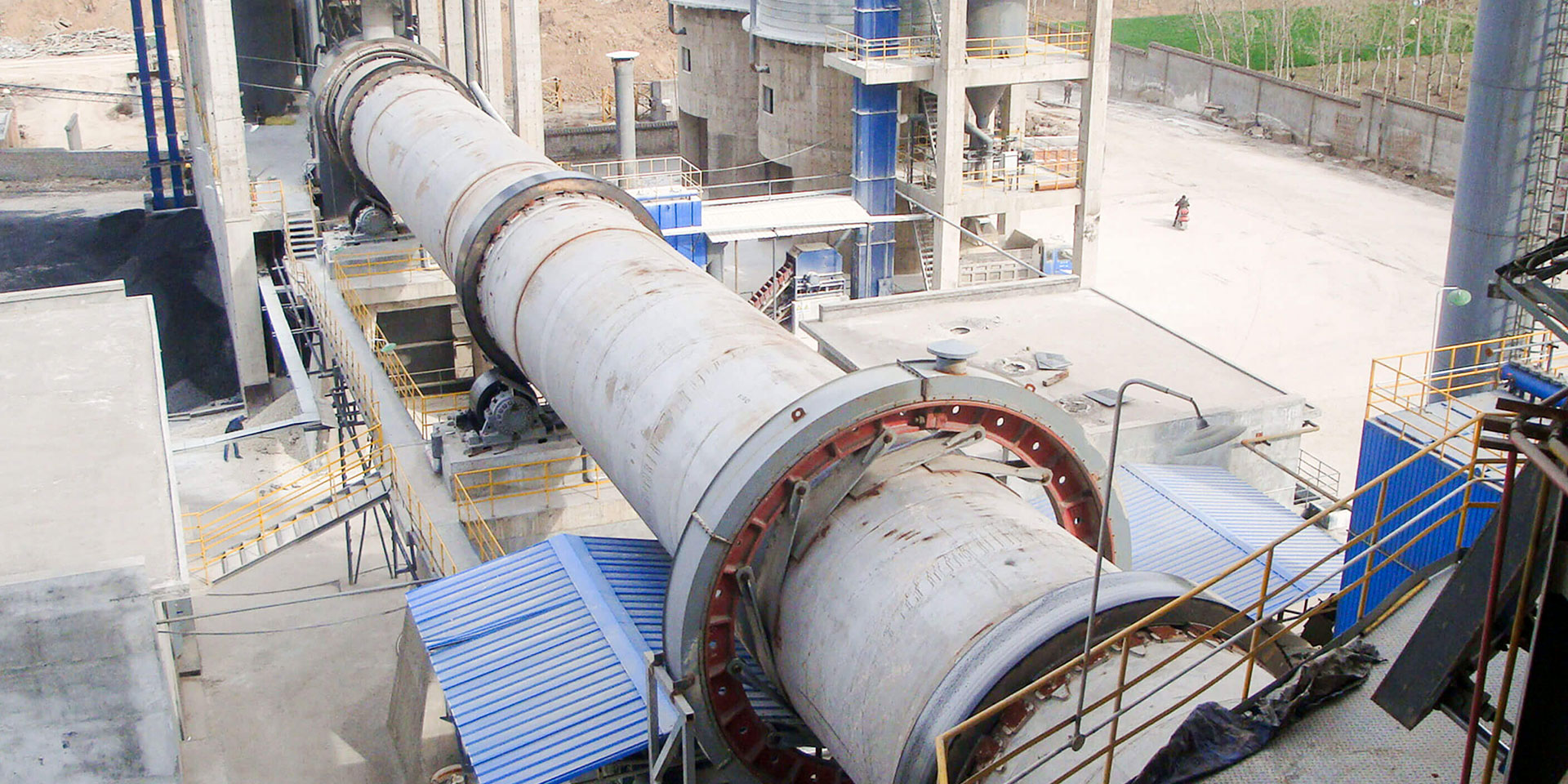

CONTACT USRotary kiln refers to rotary calcination kiln, belonging to cement building materials equipment. It is widely used in ore beneficiation, metallurgy, building materials, chemicals, electricity, petroleum, coal, transportation, fertilizer, gas and other industries. Rotary kiln is mainly used for calcination of cement clinker, including dry and wet production cement kilns. Metallurgical chemical kiln is mainly used for the magnetization and calcination of lean iron ore in metallurgical industry, the oxidation and calcination of chromite and josephinite, etc.

1. Easy maintenance and installation: Larger rotary kiln is equipped with auxiliary transmission drive for the cylinder to rotate at very low speed, which can meet the needs of installation and maintenance.

2. Good sealing performance: In order to prevent cold air from entering and smoke dust overflowing cylinder, there is reliable sealing devices on the feed end (tail) and discharge end (head) of the cylinder.

According to different processing materials, rotary kiln can be divided into cement kiln, metallurgical chemical kiln and lime kiln. According to their production purposes, the rotary kiln produced by our company can be divided into: ceramsite rotary kiln, metallurgical rotary kiln, chemical rotary kiln, white ash rotary kiln and active lime rotary kiln, etc. Of all, cement

A super-large-scaled modern green industrial workshop 260000 square meters, large and medium-sized gold processing, maohan, assembly equipment more than 600 sets.

CONTACT US

| Product Specification (m) |

Kiln dimensions | Motor power (kw) |

Total weight (t) |

note | ||||

| Diameter (m) |

Length (m) |

Obliquity (%) |

Capacity (t/d) |

Rotation speed (r/min) |

||||

| Φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149.61 |

----- |

| Φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187.37 | ----- |

| Φ2.5×54 | 2.5 | 54 | 3.5 | 280 | 0.48-1.45 | 55 | 196.29 |

outside disassemble kiln |

| Φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 198.5 | ------ |

| Φ2.8×44 | 2.8 | 44 | 3.5 | 450 | 0.437-2.18 | 55 | 201.58 |

outside disassemble kiln |

| Φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 210.94 | ------ |

| Φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 |

outside disassemble klin |

| Φ3.0×60 | 3 | 60 | 3.5 | 800 | 0.3-2 | 100 | 310 | ------ |

| Φ3.2×50 | 3.5 | 50 | 4 | 1000 | 0.6-3 | 125 | 278 |

disassemble klin |

| Φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 |

kiln with preheater precalcine |

| Φ3.5×54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 | 363 |

kiln with prehrater precalcine |

| Φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 |

Generating klin for usimg ofterheat |

| Φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 |

klin with prehrater precalcine |

| Φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 |

klin with prehrater precalcine |

| Φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.41-4.07 | 375 | 633 |

klin with prehrater precalcine |

| Φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 |

klin with prehrater precalcine |

| Φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 |

klin with prehrater precalcine |

| Φ4.7×74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 | 849 |

klin with prehrater precalcine |

| Φ4.8×74 | 4.8 | 74 | 4 | 5000 | 0.396-3.96 | 630 | 899 |

klin with prehrater precalcine |

| Φ5.0×74 | 5 | 74 | 4 | 6000 | 0.35-4 | 710 | 944 |

klin with prehrater precalcine |

| Φ5.6×87 | 5.6 | 87 | 4 | 8000 | Max4.23 | 800 | 1265 |

klin with prehrater precalcine |

| Φ6.0×95 | 6 | 95 | 4 | 10000 | Max5 | 950×2 | 1659 |

klin with prehrater precalcine |

| Product Specification (m) |

Capacity (t/d) |

Rotation speed (r/min) |

| Φ2.5×40 | 180 | 0.44-2.44 |

| Φ2.5×50 | 200 | 0.62-1.86 |

| Φ2.5×54 | 280 | 0.48-1.45 |

| Φ2.7×42 | 320 | 0.10-1.52 |

| Φ2.8×44 | 450 | 0.437-2.18 |

| Φ3.0×45 | 500 | 0.5-2.47 |

| Φ3.0×48 | 700 | 0.6-3.48 |

| Φ3.0×60 | 800 | 0.3-2 |

| Φ3.2×50 | 1000 | 0.6-3 |

| Φ3.3×52 | 1300 | 0.266-2.66 |

| Φ3.5×54 | 1500 | 0.55-3.4 |

| Φ3.6×70 | 1800 | 0.25-1.25 |

| Φ4.0×56 | 2300 | 0.41-4.07 |

| Φ4.0×60 | 2500 | 0.396-3.96 |

| Φ4.2×60 | 2750 | 0.41-4.07 |

| Φ4.3×60 | 3200 | 0.396-3.96 |

| Φ4.5×66 | 4000 | 0.41-4.1 |

| Φ4.7×74 | 4500 | 0.35-4 |

| Φ4.8×74 | 5000 | 0.396-3.96 |

| Φ5.0×74 | 6000 | 0.35-4 |

| Φ5.6×87 | 8000 | Max4.23 |

| Φ6.0×95 | 10000 | Max5 |